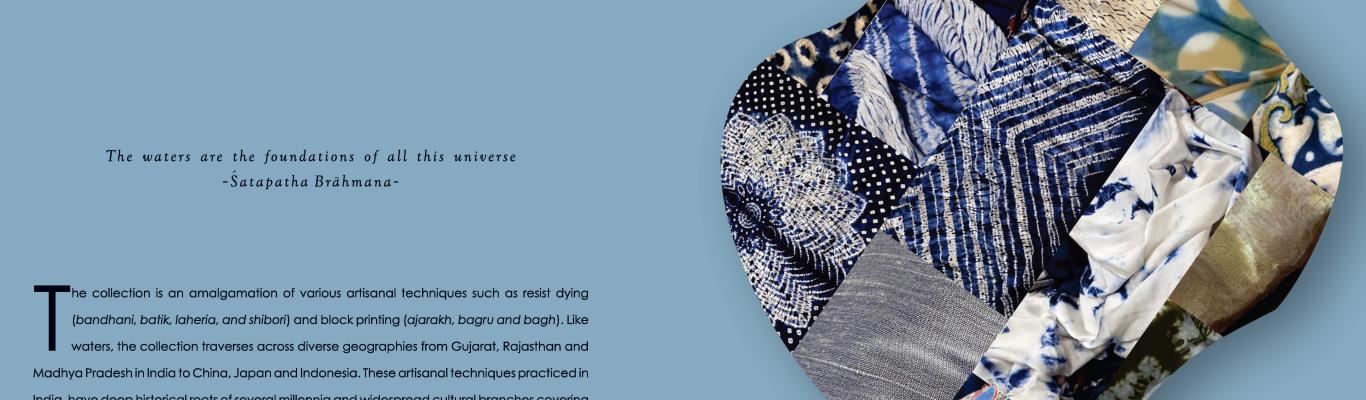

Traditional Crafts used in the Collections

G-20 Fashion Home Page | Vayu (Air) | Shuchi (Fire) | Dhara (Earth) | Jal (Water) | Nabha (Sky)

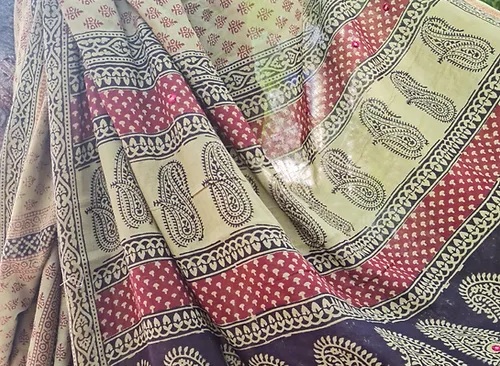

Craft Name: Bagh Printing

Location: Dhar, Madhya Pradesh

Community: Khatri

Similar Crafts in the world: Shyahi Begar, Ajrakh Paintings

Bagh Print is a traditional hand block print with natural colours, a Handicraft practiced in the village of Bagh in the Dhar district of Madhya Pradesh, India. Its name is derived from the name of the village which is also situated on the banks of the Bagh River. Bagh print fabric has distinct geometric and floral compositions with vegetable colours in red and black over a white background.

Bagh Print, was started by the community of Muslim Khatris (converted to Islam under the influence of a Sufi saint) in 1962 when they migrated from Manawar to Bagh. Their antecedents are traced to Larkana in Sindh (now in Pakistan) from where they shifted base to Marwad in Rajasthan and then to Manawar; However, the reasons for their migration from Sindh across the Indus are not clear.

The Khatris practised the block printing technique of Ajrakh in Sind, which they continued at their new place of settlement albeit with changes to meet the local trends and practices in the region; this came to be known as Bagh printing as they settled on the banks of the Bagh river in the village of the same name. In this printing technique, cotton and silk cloth are used. The cloth is subject to treatment of a blend of corroded iron fillings, alum followed by dyeing in alizarin. The designs are patterned by skilled artisans using wooden blocks. On completion of the printing process, the printed fabric is subject to repeated washing in the flowing waters of the river and then dried in the sun for a specific period to obtain a fine luster.

Process:

Block Making:

- Wood is first cut to make a block and one of its sides it smoothened.

- It is then painted white on which the design is drawn or traced.

- The engraving and carving are done as per the design to form a block with the printing surface in relief.

- Holes are drilled up to two centimeters on the sides of the block to avoid air bubbles. This also ensures that the block doesn't stick to the fabric due to the vacuum created during stamping with the block.

- Handles are attached for better grip.

- Blocks are of two types: rekh and gad. Gad is a 'filling block' and is used for printing the bigger areas while Rekh is used for intricate lines that are done as outlines or for giving details inside the spaces.

Fabric Treatment:

- Fabric is first soaked in water for about twelve hours and then suckled with legs to remove the starch.

- Fabric is then bleached and washed in 'sanchorapaani' (a mix of rock salt and water).

- Harada powder (obtained from a type of tree) is mixed in water and the fabric is washed in it for about five minutes. This provides it an off-white/ off-yellow tinge and also aids in strengthening the tones of black and red colours printed later. It is then dried in the sun.

Printing:

- Ferrous sulphate (used for making black dye) or alum (used for preparing red dye) is first mixed with water.

- A paste right for the consistency of printing is made.

- Colours containing trays are covered with a bamboo frame.

- On top of this a felt piece is kept to avoid excessive sticking of colours. Through this the colours is picked up in appropriate amount by the portion of the block that is to be printed.

- The fabric to be printed upon is spread over the table that has several layers of jute, blanket and cotton cloth.

Washing:

- The next part of the process is to take the printed bundles to be washed in running water.

- The fabric is first cleansed in flowing water and then beaten against stones. That clears the material of any excess colours. This requires a lot of care else stains and smudges would appear on the printed surface.

- Fabric is then left to dry in the sun.

Boiling:

- The dried fabric is then boiled using Alizarin and Dhawde ka phool to get red colours.

- Fabric is washed for one more time and dried.

Source :

https://craftatlas.co/crafts/bagh-print

https://www.dsource.in/resource/block-prints-bagh

https://static.wixstatic.com/media/fa0928_23e37494430b40298f5189d85fd610f5~mv2.jpg/v1/fill/w_500,h_667,al_c,q_80,usm_0.66_1.00_0.01,enc_auto/fa0928_23e37494430b40298f5189d85fd610f5~mv2.jpg

Craft Name: Batik Printing

Location: Mundra, Gujarat

Community: Khatri

Similar Crafts in the world: Indonesian batik, Chinese batik, Batik in Madhya Pradesh and West Bengal

Hand Batik Printing is an art of decorating the cloth using wax as a resist. It is believed that the word Batik is derived from the Malay word ‘ambatik’. Batik print is a very old form of art, with evidence of early batik print discovered in the Middle East, Egypt, Peru, Japan, Turkistan, Europe as well as Central Asia (India and China) as far back as 2000 years ago. Batik was initially practiced in China as early as the Sui Dynasty (581 – 618CE). The history of Indian batik can be traced back to the 1st century CE. During this period, Khatri community in Gujarat were the only set of artisans for this Batik art. Now there is no single community involved in this work, as artisans of various communities and regions are now trained in hand batik print. In India, Batik printing is done in parts of Rajasthan, Andhra Pradesh, Maharashtra, West Bengal, Madhya Pradesh and Gujarat.

Batik print is a unique technique of colouring or ornamenting the cloth by hiding a part of it with a wax coat and then dyed so that the waxed area keeps its original colour and when the wax is removed, the contrast between the dyed and undyed areas makes the pattern. Batik art involves three main stages of waxing, dyeing and dewaxing (removing the wax). Depending on the number of colours the wax can be applied in multiple stages starting from the lightest to the darkest colours.

Process:

- The fabric is washed to remove starch.

- Wooden printing block or special wax pen is dipped in melted wax.

- The design are hand printed with a block or hand drawn with the wax pen.

- The wax coated fabric is dyed.

- Further wax is applied to reserve the area of the new colours and the fabric is dyed in a second colours. This step is repeated as per the number of distinct colours required.

- After dyeing, wax is removed in the process of dewaxing.

- Dyed and dewaxed cloth is dried.

Source :

https://www.dsource.in/resource/hand-batik-print-ahmedabad-gujarat/introduction

https://www.avishya.com/collections/batik-printed-sarees

Craft Name: Ajrakh Printing

Location: Ajrakhpur / Dhamadka, Kutch, Gujarat / Bikaner, Rajasthan

Community: Khatri / Chippa, Vaisnav

Similar Crafts in the world: Bagh Printing, Shyahi Begar

Ajrakh is believed to be originated from the Arabic word Azrak that refers to the color blue. Ajrakh printing, practiced in the district of Kutch in Gujarat is done by the Khatri community. It was traditionally done on both sides of the fabric usually in blue colour obtained from indigo, and a red and white pattern from madder. Kutch is one of India's leading areas for block printing and dyeing.

These fabrics were usually used as a shoulder cloth, turban (head wrap) and as men’s lower draped garment – lungis by the Meghwals and Ahirs (cattle herders of Kutch region). As per the craftsmen, these fabrics were made for the cattle-rearing people of the Sindh region and worn at night when they took their cattle to the forest for grazing. It was believed that these fabrics protected the wearers from wild animals due to their vivid blue and green colours. Also, the blue colour in Ajrakh printing is believed of keeping warm in winter and cold in summer.

Ajrakh printing involves many stages of printing with mordants, washing and dyeing with natural dyes.

Floral and geometrical designs in the colours of red, blue and black predominate in Ajrakh printing, which is traditionally worn by men as lungi, turban and shoulder cloth.

Process:

- The Fabric is treated with harda (myrobalan) powder

- The treated fabric is spread on the printing table and printed with outline blocks (rekh) with a white print on both sides of the fabric. This white print reserves the areas of the fabric to which lime and Arabic gum are applied.

- The white printed fabric is dried under sunlight for about 15- 20 minutes.

- A black print mixture is printed with blocks locally called as kat.

- Red colour is printed after the fabric is dried with black print.

- The fabric is then immersed for about 5 to 10 minutes in indigo vat.

Source :

https://www.dsource.in/resource/ajrakh-printing-ajrakhpur-gujarat/introduction

https://www.dsource.in/resource/ajrakh-printing-ajrakhpur-gujarat/making-process

https://maiwa.com/pages/ajrakh

Craft Name: Bandhani

Location: Bhuj, Kutch, Gujarat

Community: Khatri

Similar Crafts in the world: Shibori, Sungadi, Thigma

Bandhani also known as “Bandhej” is a tie & dye craft. The term bandhani refers to the technique of crafting patterned textiles by resisting parts of a fabric by tying knots on it before it is dyed. This craft is believed to have travelled from Sindh to Gujarat via Rajasthan and further on to Madhya Pradesh and Tamil Nadu. The Kutch bandhani is renowned for its extremely fine dots and sophisticated composition. Bandhani is used for both everyday attire and ceremonial clothing. The social, economic and cultural connotations are determined by the base fabric satin silk (gajji), fine cotton muslin or wool. This craft is practiced in Kutch, Jamnagar and some parts of Rajasthan. Traditionally tying is done by the women of the house while pattern-making and dying are done by the men. The tying varies from small to big. The smaller dotted designs sell at a higher price considering the intricate patterns. Various type of bandhani is done based on technique to resist the fabric like stitch resist, clamping etc.

Process:

- The design is drawn on the tracing paper and punched-marked (pierced) using a needle.

- The design is then transferred to the fabric by rubbing fugitive ink through the tracing sheet piercing using a brush or cotton.

- The fabric is then sent for tying, which is usually done by the women in their spare time. The tying is done using a metal nail (nau), which acts as a false nail, a Glass or plastic tube (bhungari) and thread. This process of tying knots is repeated throughout the design at regular intervals.

- Once the tying is done, the fabric is washed in hot water to remove the fugitive ink and subsequently dyed in the desired colour.

- Then the fabric is washed, followed by drying in the shade.

Source :

https://www.dsource.in/resource/bandhini/introduction

https://www.dsource.in/resource/bandhini/process

https://peachmode.com/blogs/peachmode/all-you-need-to-know-about-bandhani

Craft Name: Lehariya

Location: Bhuj, Kutch, Gujarat / Jaipur & Churu, Rajasthan

Community: NA

Similar Crafts in the world: Shibori, Bandhani

Leheria, A Rajasthani word signifies wave forms of water, from which almost all of its designs are inspired. The craft is based on the resist dyeing method of patterning the cloth. The other popular resist dyeing techniques are - bandhani, batik and shibori. The Leheria technique of tie and dye is practiced in parts of Rajasthan such as Jodhpur, Udaipur, and Nathdwara and in the pink city Jaipur, the state capital of Rajasthan.

In this technique, the cloth piece is twisted and knots are tied at a precise gap all over the fabric with the help of a thread, which resists the dye thus forming the design of alternate colours patches and small gap of whites, which Leheria is famous for. Leharia cloth has always been and continues to be famous among Rajput clans for making the male, Paggar / Pagri, the Rajasthani style of turban considered auspicious and dignified, used during ceremonies such as marriage, puja and other festivals. For women in Rajasthan, the leheriya is popular as a dupatta (Scarf) and saree. Leheria sarees are especially preferred by the Marwari community.

Process:

- The cloth is washed off to remove any residue such as starch, sand, dirt etc.

- The wet cloth is then completely dried for further process.

- It is twisted in its length (usually by two people stretching the fabric from both its ends) so that it creates enough tension, and then is transferred onto a wooden stand.

- The twisted cloth piece is wrapped around the wooden pole firmly, so that it does not loosen. It is then tightly tied by threads at regular intervals as per the intended pattern. The threads act as a resisting agent, from dyes.

- Knotting is done in a precise and regular interval of gap onto the cloth, parallel to each other, which gives the cloth its signature waveform after dyeing.

- After the knotting the, cloth is dipped in water, to make it absorbent to the dyes.

- The wet fabric is dyed in the required colours and the knotting and tying is repeated for multiple colours and dye cycles.

- The dyed fabric is dried and the knots are carefully removed after drying, to avoid damage to the cloth.

- It is washed for one final time and dried.

Source :

https://www.google.com/imgres?imgurl=http%3A%2F%2Fcdn.shopify.com%2Fs%2Ffiles%2F1%2F0053%2F9122%2F0771%2Fproducts%2Fimage_0e8ad986-c90e-40a6-a98a-0c69b2517db2.jpg%3Fv%3D1660048198&tbnid=9yVBm_PFrUzpNM&vet=12ahUKEwjr4qzm2Pn_AhULvmMGHSrpCnUQMygoegUIARCvAg..i&imgrefurl=https%3A%2F%2Fwww.rootshandloom.com%2Fen-qa%2Fproducts%2Fpink-orange-lehariya-saree&docid=CZi8GR9vz9ZkOM&w=1024&h=1024&itg=1&q=lehariya&hl=en-GB&client=safari&ved=2ahUKEwjr4qzm2Pn_AhULvmMGHSrpCnUQMygoegUIARCvAg

https://dsource.in/sites/default/files/resource/leharia-tie-and-dye-jaipur/downloads/file/leharia-tie-and-dye-jaipur.pdf